For handling and storing of various kinds of bulk materials there is possibility to make use of several types of stockyard machines. Selection of the most convenient type should consider:

- storing

- homogenization

Protection against atmospheric conditions:

- outdoor stockyard

- indoor stockyard

Volume of stored material – storing capacity

Number of stored material:

- separately each grade

- common storing

- homogenization

Stored material properties:

- type

- granularity

- humidity

- adhesiveness

In order to be able to decide on the suitable type it is necessary to consider other factors, for example:

- stacking and reclaiming capacity

- simultaneous stacking and reclaiming

- shape and area of the stockyard

After considering of all circumstances we can use the offer of several types of stockyard machines:

Gantry belt stacker and Gantry bucket-chain reclaimer

These machines are used for outdoor stockyards with the need of big capacity and the best carried out homogeneity.

Here it is possible to stock various types of materials on individual piles and reclaim them according to needs, or as it has been said, we can carry out controlled homogenization of identical material from various suppliers or from various deposits.

Machine capacities:

- stacking 800 m³/hour

- reclaiming 400 m³/hour

Stockyard – 50 m x 1000 m

Advantage of these stockyards is the mixing of the already stocked blend before further use and saving of a part or entire equipment for blend preparation.

Gantry stacker/reclaimer

This is the combination of gantry belt stacker and gantry bucket-chain reclaimer into one machine. This double-purpose machine provides advantages of individual stackers and reclaimers but can be used only either for stacking or for reclaiming.

Machine capacities are approximately halfway compared to the separate machines.

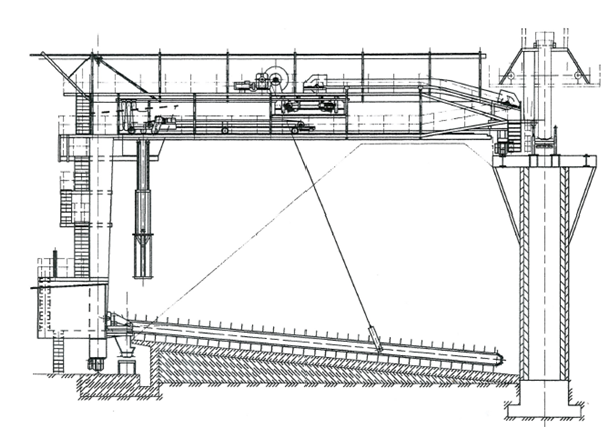

Side scrapers

The big advantage of this type is using in the indoor stockyards for the possibility to store material without influence of atmospheric conditions. The stockyard is formed by longitudinal supporting wall both for placing of upper track and support the stockyard structure. Between tracks in transverse direction the reinforcing walls serve as boxes walls for storing of particular sorts of material.

The storing capacity may be doubled by mirror design of the same equipment situated on the opposite side of the supporting wall.

Different sorts of material are stacked by independent system of travelling and reversible conveyors.

Reclaiming is made by the side scraper with capacity 350 m³/hour. This equipment works in automatic mode according to selected program.

Semi-gantry stacker/reclaimer

The semi-gantry stacker/reclaimer is used in similar way as in previous case with the possibility of homogenization of the stacked material; the stacking is carried out by the machine.

This double-purpose machine is predominantly determined for high capacity outdoor stockyards due to big dimensions of the stockyard structure without central supporting.

The machine may be used only either as a stacker or as a reclaimer.

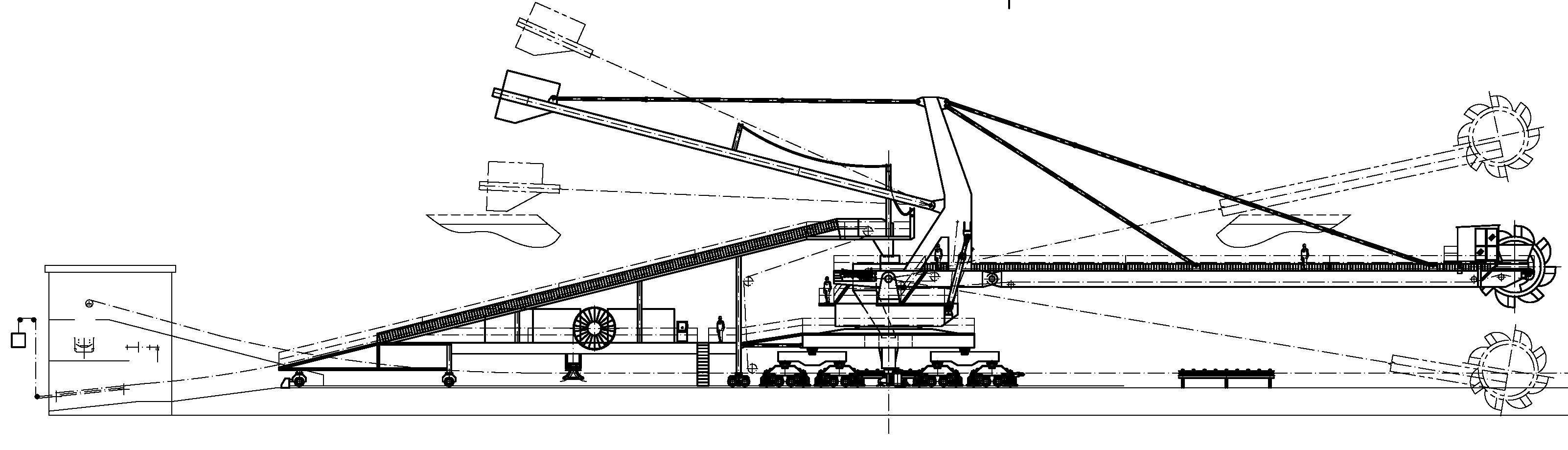

Bucket-wheel stacker/reclaimer

The piles of material are situated on both sides of the machine runway in whose axis the feeding and removing stockyard belt conveyor with the possibility of continuous transfer of material directly to bunkers is located.

By means of a set of conveyors and transfer points the material is stacked in a sickle-shaped way or other way by selected program. Reclaiming is carried out by the chamber-less wheel and chute on the jib reverse conveyor and then through the transfer point on the stockyard belt conveyor. This double-purpose machine ensures low degree of homogenization and enables either only stacking or reclaiming

Output capacity is approximately 1000 m³/hour.

These basic types of machines for bulk handling operations are used in power plants, metallurgical plants, cement plants and the like. It is possible to customize them in compliance with safety and environmental protection aspects.